PRI Training has a series of MedAccred courses designed to provide support for OEMs, Contract Manufacturers, Suppliers, Auditors, Staff Engineers and anyone involved in the MedAccred critical process accredidation. Courses are available in the following categories:

-

MedAccred Process Validation

-

MedAccred Audit Criteria Preparation

-

MedAccred : Root Cause Corrective Action

Contact Us about scheduling a private training at your facilities.

-

MedAccred Process Validation

The MedAccred Process Validation courses cover many different types and levels of manufacturing in the medical device industry. It has been divided into 3 parts.

Part 1

provides the basics of Process Validation as initiated by the Global Harmonization Task Force (GHTF) document on Process Validation. This document is considered the cornerstone for medical device process validation strategy and focuses on the general applicability to manufacturing (including service and installation) processes for medical devices.Part 2

expands on what was learned in Part 1, using examples, and discussion of key elements for establishing the process for process validation, expanding on statistical approaches, and explaining recent regulatory direction, emphasizing the risk-based approach, verification-versus-validation, the movement toward continuous verification/validation, and process validation issues from recent Food and Drug Administration (FDA) auditing.

MedAccred Audit Criteria Preparation

These courses prepare you for the MedAccred audit process and review audit criteria and common non-comforances for your specific critical process. Audit Criteria Preparation courses are available in the following critical processes:

• Extrusion

• Injection Molding

• Mechanical Assembly

• Cable & Harness Assemblies

• Welding

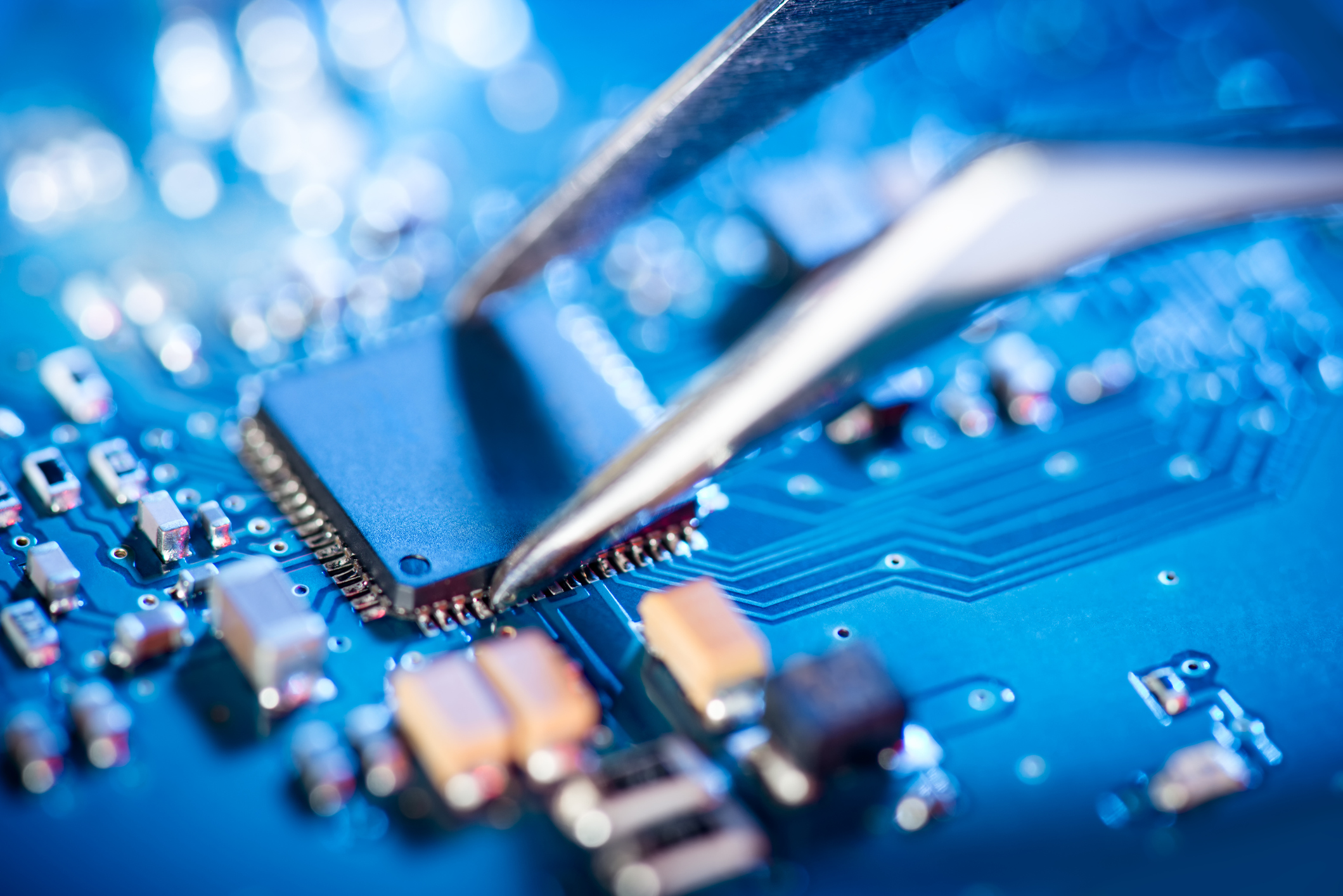

• Printed Circuit Boards Assemblies

• Heat Treating

• Sterile Device Packaging

MedAccred Root Cause Corrective Action

This course gives learners an understanding of the basic concepts of Root Cause Corrective Action (RCCA) and Corrective Action Preventative Action (CAPA), and shows how to apply those concepts, to eliminate errors and prevent defects re-occurring.